技术规格

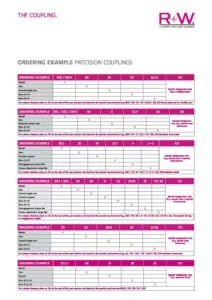

| SK2 1.5 | SK2 1.5 F | SK2 2 | SK2 2 F | SK2 4.5 | SK2 4.5 F | SK2 10 | SK2 10 F | SK2 15 | SK2 15 F | SK2 30 | SK2 30 F | SK2 60 | SK2 60 F | SK2 80 | SK2 80 F | SK2 150 | SK2 150 F | SK2 200 | SK2 300 | SK2 300 F | SK2 500 | SK2 500 F | SK2 800 | SK2 800 F | SK2 1500 | SK2 1500 F | ||||||||||||||||||||||

| 型号 | SK2 1.5 42 | SK2 1.5 42 F | SK2 2 46 | SK2 2 51 | SK2 2 46 F | SK2 2 51 F | SK2 4.5 57 | SK2 4.5 65 | SK2 4.5 57 F | SK2 4.5 65 F | SK2 10 65 | SK2 10 74 | SK2 10 65 F | SK2 10 74 F | SK2 15 75 | SK2 15 82 | SK2 15 75 F | SK2 15 82 F | SK2 30 87 | SK2 30 95 | SK2 30 87 F | SK2 30 95 F | SK2 60 102 | SK2 60 112 | SK2 60 102 F | SK2 60 112 F | SK2 80 115 | SK2 80 127 | SK2 80 117 F | SK2 80 129 F | SK2 150 116 | SK2 150 128 | SK2 150 118 F | SK2 150 130 F | SK2 200 128 | SK2 200 140 | SK2 300 139 | SK2 300 153 | SK2 300 142 F | SK2 300 156 F | SK2 500 163 | SK2 500 177 | SK2 500 167 F | SK2 500 181 F | SK2 800 190 | SK2 800 201 F | SK2 1500 223 | SK2 1500 232 F |

| 总长度(mm) | 42 | 42 | 46 | 51 | 46 | 51 | 57 | 65 | 57 | 65 | 65 | 74 | 65 | 74 | 75 | 82 | 75 | 82 | 87 | 95 | 87 | 95 | 102 | 112 | 102 | 112 | 115 | 127 | 117 | 129 | 116 | 128 | 118 | 130 | 128 | 140 | 139 | 153 | 142 | 156 | 163 | 177 | 167 | 181 | 190 | 201 | 223 | 232 |

| 孔径范围(mm) | 3-8 | 3-8 | 4-12 | 4-12 | 4-12 | 4-12 | 5-14 | 5-14 | 5-14 | 5-14 | 6-16 | 6-16 | 6-16 | 6-16 | 10-26 | 10-26 | 10-26 | 10-26 | 12-30 | 12-30 | 12-30 | 12-30 | 15-32 | 15-32 | 15-32 | 15-32 | 19-42 | 19-42 | 19-42 | 19-42 | 19-42 | 19-42 | 19-42 | 19-42 | 24-45 | 24-45 | 30-60 | 30-60 | 30-60 | 30-60 | 35-60 | 35-60 | 35-60 | 35-60 | 40-75 | 40-75 | 50-80 | 50-80 |

| 外径(mm) | 19 | 19 | 25 | 25 | 25 | 25 | 32 | 32 | 32 | 32 | 40 | 40 | 40 | 40 | 49 | 49 | 49 | 49 | 55 | 55 | 55 | 55 | 66 | 66 | 66 | 66 | 81 | 81 | 81 | 81 | 81 | 81 | 81 | 81 | 90 | 90 | 110 | 110 | 110 | 110 | 123 | 123 | 123 | 123 | 134 | 134 | 157 | 157 |

| 径向偏差±(mm) | 0.15 | 0.15 | 0.15 | 0.20 | 0.15 | 0.20 | 0.20 | 0.25 | 0.20 | 0.25 | 0.20 | 0.30 | 0.20 | 0.30 | 0.15 | 0.20 | 0.15 | 0.20 | 0.20 | 0.25 | 0.20 | 0.25 | 0.20 | 0.25 | 0.20 | 0.25 | 0.20 | 0.25 | 0.20 | 0.25 | 0.20 | 0.25 | 0.20 | 0.25 | 0.25 | 0.3 | 0.25 | 0.3 | 0.25 | 0.3 | 0.3 | 0.35 | 0.3 | 0.35 | 0.35 | 0.35 | 0.35 | 0.35 |

| 角向偏差±(degree) | 1 | 1 | 1 | 1.5 | 1 | 1.5 | 1.5 | 2 | 1.5 | 2 | 1.5 | 2 | 1.5 | 2 | 1 | 1.5 | 1 | 1.5 | 1 | 1.5 | 1 | 1.5 | 1 | 1.5 | 1 | 1.5 | 1 | 1.5 | 1 | 1.5 | 1 | 1.5 | 1 | 1.5 | 1.5 | 2 | 1.5 | 2 | 1.5 | 2 | 2 | 2.5 | 2 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| 扭矩调节范围(Nm) | 0.1-0.6 0.4-1 0.8-1.5 | 0.3-0.8 0.6-1.3 | 0.2-1.5 0.5-2 | 0.2-1.5 0.5-2 | 0.2-1 0.7-2 | 0.2-1 0.7-2 | 1-3 3-6 | 1-3 3-6 | 2.5-4.5 | 2.5-4.5 | 2-6 4-12 | 2-6 4-12 | 2-5 5-10 | 2-5 5-10 | 5-10 8-20 | 5-10 8-20 | 7-15 | 7-15 | 10-25 20-40 | 10-25 20-40 | 8-20 16-30 | 8-20 16-30 | 10-30 25-80 | 10-30 25-80 | 20-40 30-60 | 20-40 30-60 | 20-70 30-90 | 20-70 30-90 | 20-60 40-80 | 20-60 40-80 | 20-70 45-150 80-180 | 20-70 45-150 80-180 | 20-60 40-80 80-150 | 20-60 40-80 80-150 | 30-90 60-160 120-240 | 30-90 60-160 120-240 | 100-200 150-240 200-320 | 100-200 150-240 200-320 | 120-180 160-200 | 120-180 160-200 | 80-200 200-350 300-500 | 80-200 200-350 300-500 | 60-150 100-300 250-500 | 60-150 100-300 250-500 | 400-650 500-800 650-850 | 200-400 450-800 | 650-800 700-1,200 1,00-1,800 | 1,000-1,250 1,250-1,500 |

特性

- 材料:

- 波纹管:高性能不锈钢

- 夹紧系统:硬化钢

- 夹紧轴套:最大规格80及以下-铝,规格150及以上-钢

- 温度范围:

- -30°C 至 +120°C(-22°F 至 +248°F)

- 设计:

- 两个锥形夹紧轴套配备六个紧固螺钉

- 夹紧系统:弹簧负载系统

- 可用的功能系统:

- W = 单点/自动复位(标准)

- D = 多点/自动复位

- G = 封闭式

- F = 失效保护式/手动复位

一般信息

- 使用寿命

- 只要不超过技术限制,R+W 安全联轴器具有抗疲劳性、耐磨和免维护

- 配合间隙

- 轴/轴套间隙为0.01 – 0.05 mm

- 特殊解决方案

- 可根据要求提供各种材料、公差、规格和性能等级,用于特殊定制应用

- ATEX(可选)

- 对于危险区域1/21和2/22,在94/9/EG标准下,安全联轴器可安全使用

189-1616-0676

189-1616-0676 021-5868 2986

021-5868 2986