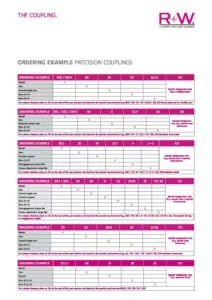

技术规格

| EK1 2 | EK1 5 | EK1 10 | EK1 20 | EK1 60 | EK1 150 | EK1 300 | EK1 400 | EK1 450 | EK1 600 | EK1 800 | EK1 2500 | EK1 4500 | EK1 9500 | ||||||||||||||||||||||||||

| 型号 | EK1 2 A | EK1 2 B | EK1 2 C | EK1 5 A | EK1 5 B | EK1 5 C | EK1 10 A | EK1 10 B | EK1 10 C | EK1 20 A | EK1 20 B | EK1 20 C | EK1 60 A | EK1 60 B | EK1 60 C | EK1 150 A | EK1 150 B | EK1 150 C | EK1 300 A | EK1 300 B | EK1 300 C | EK1 400 A | EK1 400 B | EK1 400 C | EK1 450 A | EK1 450 B | EK1 450 C | EK1 600 A | EK1 600 B | EK1 600 C | EK1 800 A | EK1 800 B | EK1 800 C | EK1 2500 A | EK1 2500 B | EK1 4500 A | EK1 4500 B | EK1 9500 A | EK1 9500 B |

| 额定扭矩(Nm) | 2 | 2.4 | 0.5 | 9 | 12 | 2 | 12.5 | 16 | 4 | 17 | 21 | 6 | 60 | 75 | 20 | 160 | 200 | 42 | 325 | 405 | 84 | 410 | 520 | 90 | 530 | 660 | 95 | 700 | 840 | 150 | 950 | 1,100 | 240 | 1,950 | 2,450 | 5,000 | 6,200 | 10,000 | 12,500 |

| 孔径范围(mm) | 3-9 | 3-9 | 3-9 | 6-15 | 6-15 | 6-15 | 6-18 | 6-18 | 6-18 | 8-25 | 8-25 | 8-25 | 12-32 | 12-32 | 12-32 | 19-38 | 19-38 | 19-38 | 20-45 | 20-45 | 20-45 | 25-50 | 25-50 | 25-50 | 28-60 | 28-60 | 28-60 | 30-70 | 30-70 | 30-70 | 32-80 | 32-80 | 32-80 | 30-95 | 30-95 | 40-130 | 40-130 | 50-170 | 50-170 |

| 外径(mm) | 15 | 15 | 15 | 25 | 25 | 25 | 32 | 32 | 32 | 42 | 42 | 42 | 56 | 56 | 56 | 66.5 | 66.5 | 66.5 | 82 | 82 | 82 | 95 | 95 | 95 | 102 | 102 | 102 | 120 | 120 | 120 | 136.5 | 136.5 | 136.5 | 160/154 | 160/154 | 225/190 | 225/190 | 290/240 | 290/240 |

| 标准转速(rpm) | 15,000 | 15,000 | 15,000 | 15,000 | 15,000 | 15,000 | 13,000 | 13,000 | 13,000 | 12,500 | 12,500 | 12,500 | 11,000 | 11,000 | 11,000 | 10,000 | 10,000 | 10,000 | 9,000 | 9,000 | 9,000 | 8,500 | 8,500 | 8,500 | 8,000 | 8,000 | 8,000 | 6,800 | 6,800 | 6,800 | 4,000 | 4,000 | 4,000 | 3,500 | 3,500 | 3,000 | 3,000 | 2,000 | 2,000 |

| 总长度(mm) | 20 | 20 | 20 | 34 | 34 | 34 | 35 | 35 | 35 | 66 | 66 | 66 | 78 | 78 | 78 | 90 | 90 | 90 | 114 | 114 | 114 | 120 | 120 | 120 | 126 | 126 | 126 | 147 | 147 | 147 | 162 | 162 | 162 | 213 | 213 | 272 | 272 | 341 | 341 |

| 可缩短的长度(mm) | 4 | 4 | 4 | 6 | 6 | 6 | 6 | 6 | 6 | 19 | 19 | 19 | 22 | 22 | 22 | 26 | 26 | 26 | 32 | 32 | 32 | 35 | 35 | 35 | 37 | 37 | 37 | 40 | 40 | 40 | 43 | 43 | 43 | 69 | 69 | 89 | 89 | 110 | 110 |

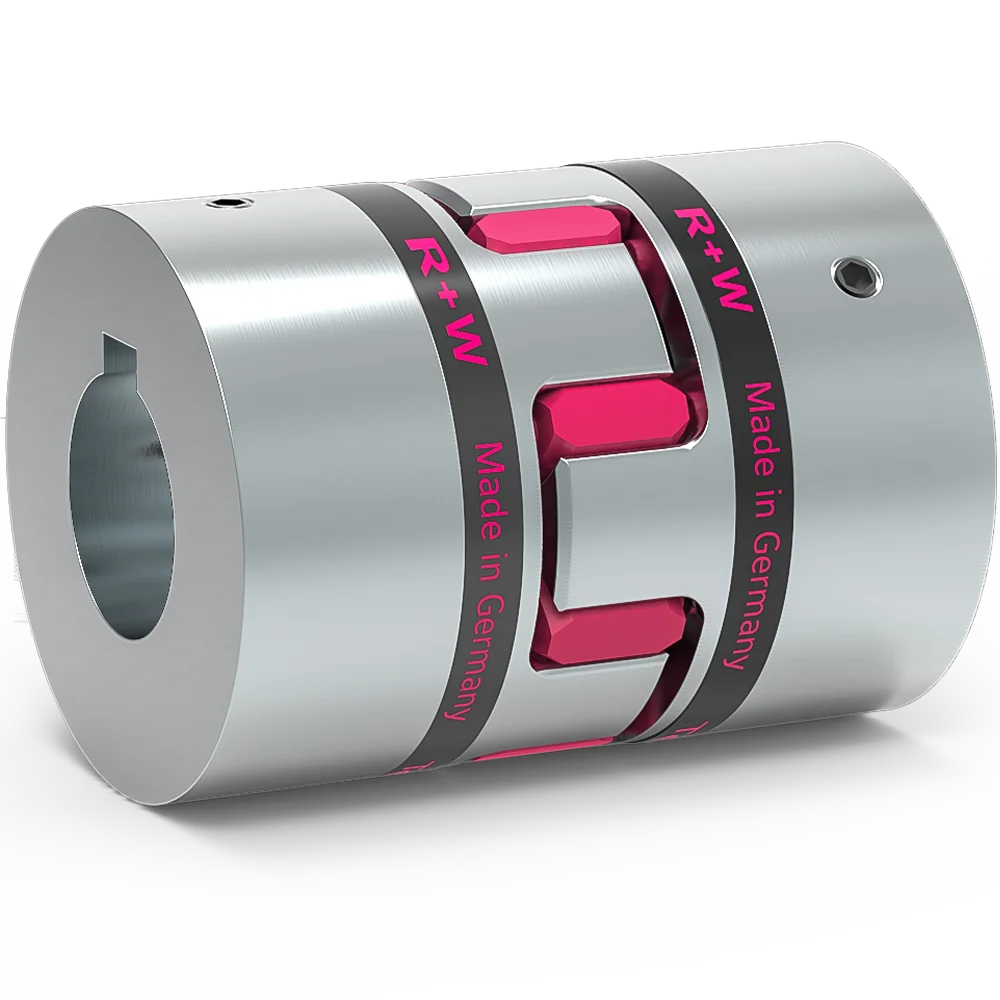

特性

- 特性

- 经济型设计

- 高同心度

- 低背隙(键槽)

- 温度范围

- 取决于弹性体

- 设计

- 两个同心加工的轴套带弯曲钳口,键槽和紧固螺钉

- 规格2500以上的弹性体包含5个弹性体

- 材料

- 轴套:规格450及以上-高强度铝,规格800及以上-钢,规格2500及以上-球墨铸铁

- 弹性体:耐磨热稳定 TPU

一般信息

- 使用寿命

- 只要不超过技术限制,R+W弹性联轴器具有抗疲劳性、耐磨和免维护

- 配合间隙

- 轴/轴套间隙为0.01 – 0.05 mm

- 特殊解决方案

- 可根据要求提供各种材料、公差、规格和性能等级,用于特殊定制应用

- ATEX(可选)

- 对于危险区域1/21和2/22,在94/9/EG标准下,弹性联轴器可安全使用

189-1616-0676

189-1616-0676 021-5868 2986

021-5868 2986